×

Search History

Chief Tech Officer

211 service speed: 2-week R&D and 1-week production

Project Manager

Experienced and expert

Industrial Designer

Service-oriented and more creative

Senior Structure Engineer

Design every component carefully

Electronics Engineer

Examine electronic accurately

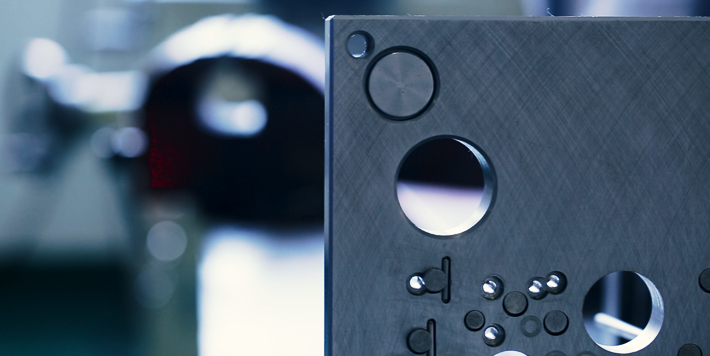

Mould Engineer

Fully responsible for model design, manufacturing, machine commissioning and material selection, etc

Production Manager

A bond that brings together marketing, product design and manufacturing

Package Designer

Skillful in design of diversified packages used for display, transportation, storage, etc.

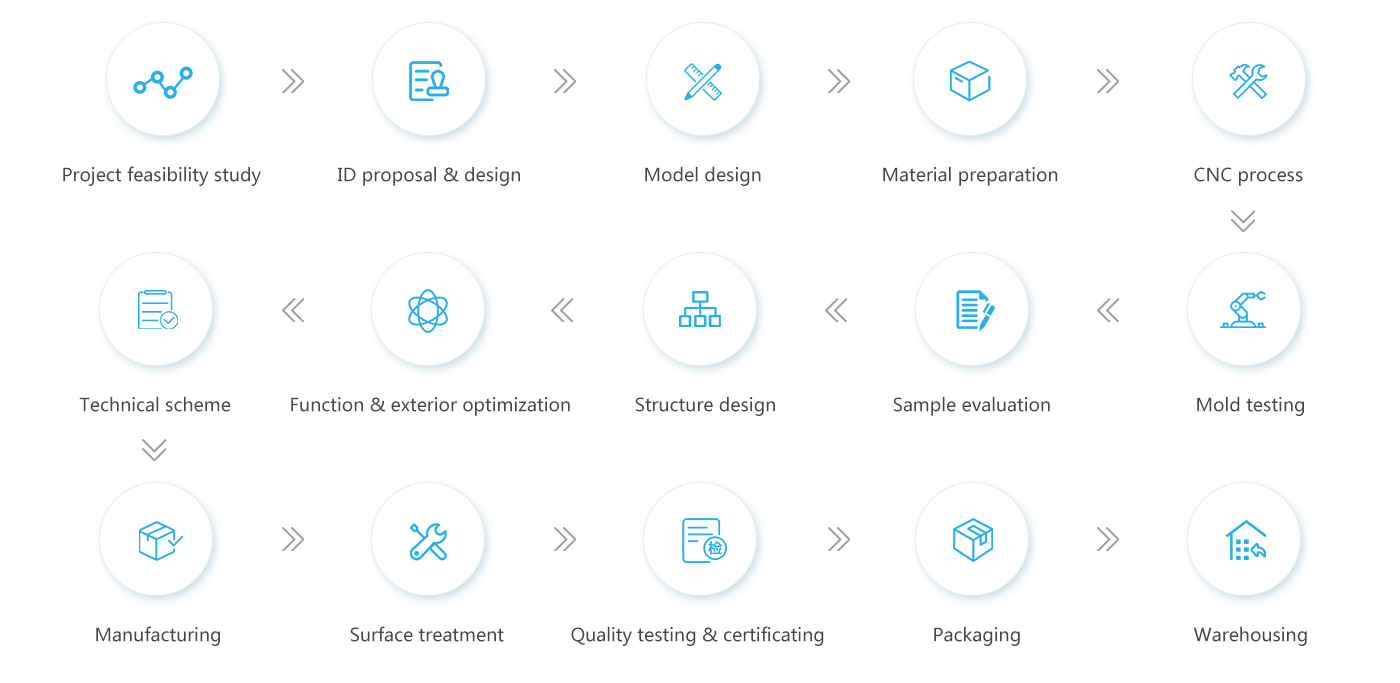

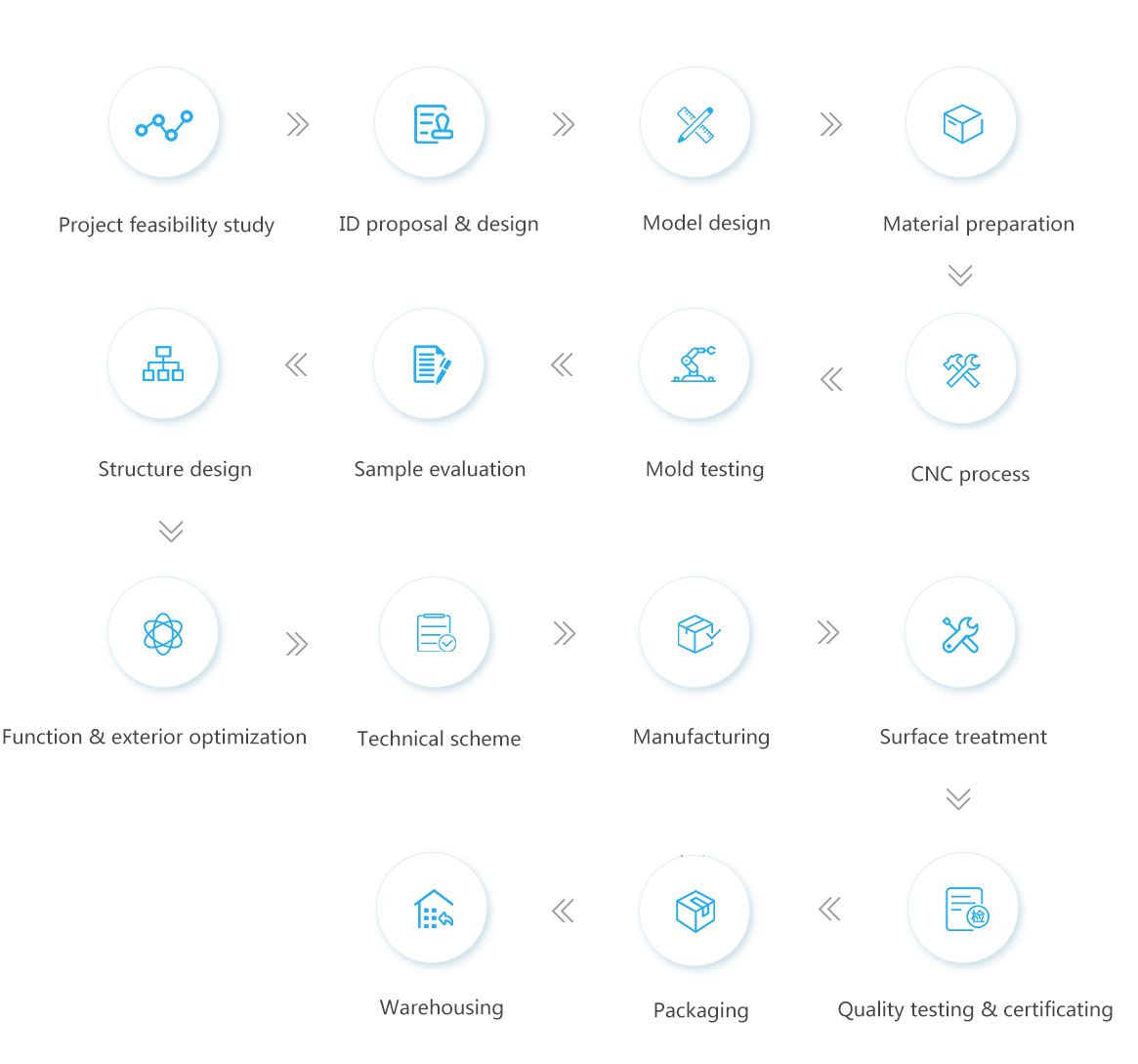

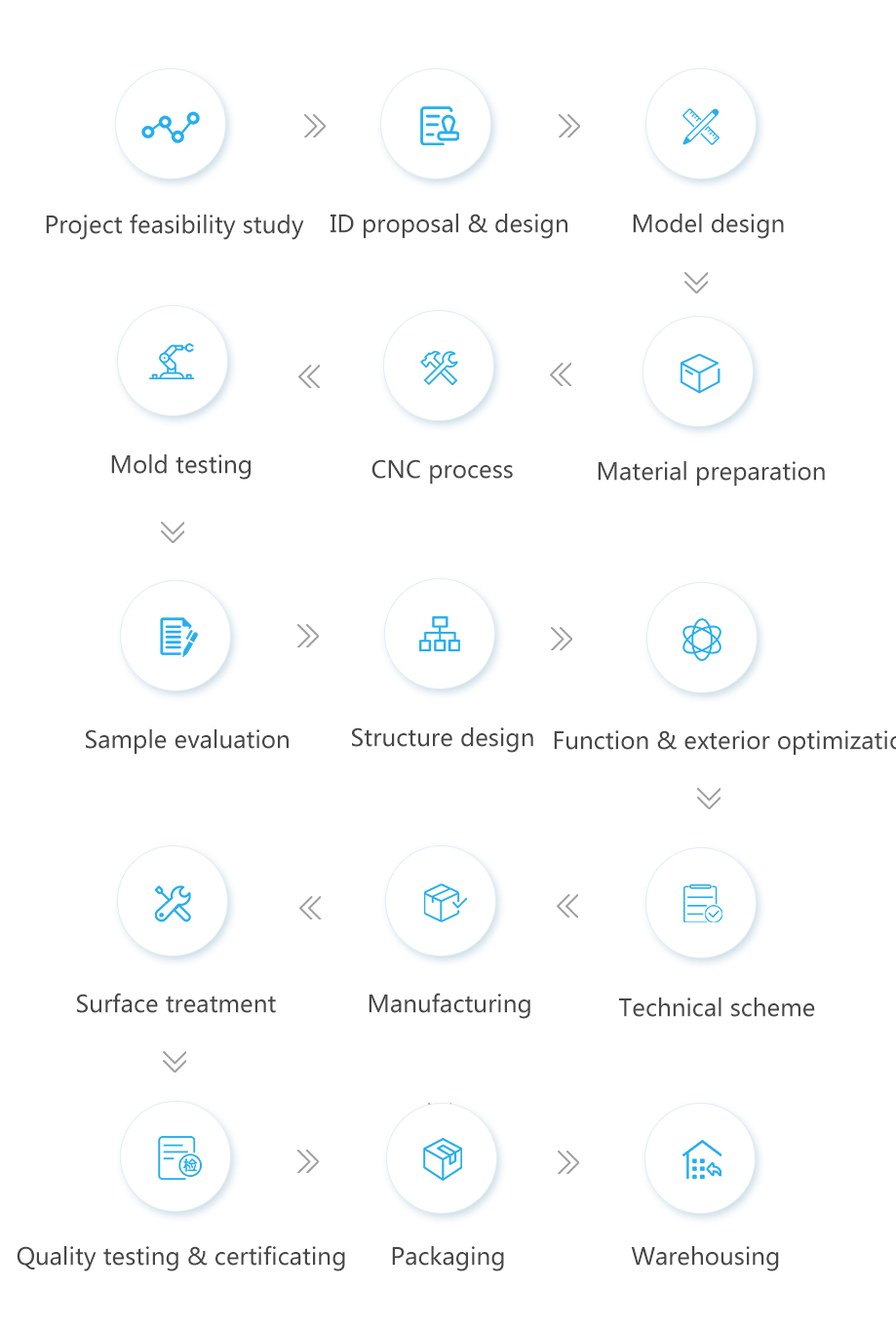

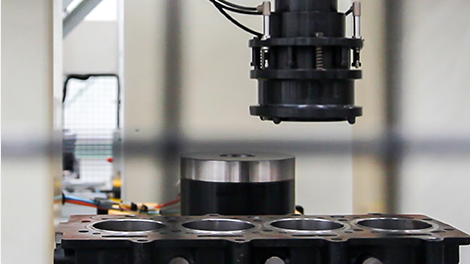

R&D Process

Technology & Application

Make the Best of Resource

Quality Guarantee System